Top selection of CNC milling machines: expert recommendations from tests and comparisons

Discover the test winners among the CNC milling machines: The best from the market at a glance

- A CNC milling machine is a state-of-the-art production device that is used to process solid materials such as wood, metal or plastic. Thanks to computer-controlled operation, this machine enables precise milling with high repeatability, regardless of the complexity of the component.

- The advantages of the CNC milling machine lie in its versatility and precision. Detailed cuts and shapes are possible with minimal error rates. In addition, they can be used just as efficiently for small quantities as for mass production, thanks to the high levels of automation and the ability to use digital templates.

- CNC milling machines have revolutionized the manufacturing process in many industries. They are indispensable in metalworking, mechanical engineering, model making and many other areas. They impressively demonstrate the innovative strength and sustainable future of modern manufacturing.

Professional CNC milling machine: purchase recommendation with expert test report and price comparison

As a passionate do-it-yourselfer and maker, I immersed myself deeply in the world of CNC milling machines and have the model TwoTrees TTC450 discovered. Priced at around $300, it stands out in its category as an excellent value for money. The high-quality workmanship and the sturdy aluminum alloy construction impressed me right from the start. Below I share my experiences and go into detail about the technical characteristics of the device. I also present a comprehensive price comparison that will help you make your decision CNC CNC Buy a milling machine will serve.

Who visites online after a CNC milling machine is looking for or about the current one CNC milling machine price If you would like to find out more, you will find what you are looking for in this specialist report. I'll show you what you should pay attention to and how you can find out whether Price for a CNC milling machine is justified and meets your requirements.

Purchase overview: Your guide for CNC milling machines

- Two trees TTC450 offers an outstanding price-performance ratio.

- Aluminum alloy and solid construction result in high quality workmanship.

- Technical details and price comparisons make the purchase decision easier Buy a CNC milling machine online.

- Insight into the most important criteria for buying and evaluating CNC Shaping.

- Comprehensive test report provides information about performance and suitability in various areas of application.

Amazon – precision and efficiency with our high-quality CNC milling machine.

Overview of CNC milling and its relevance in modern manufacturing

As someone who has been intensively involved in modern manufacturing, I am always impressed by the importance of CNC milling machines today occupy in this area. The CNC Technology has revolutionized manufacturing processes by enabling unprecedented precision and automation.

What is a CNC milling machine?

An CNC milling machine represents a groundbreaking innovation that is characterized by its ability to precisely cut workpieces. drill, engraving and milling, which simplifies production runs. This guy the industrial milling machine is operated by numerical computer control, allowing it to produce extremely complex parts that are essential to the manufacturing industry.

Use of CNC milling in industry and hobby

In the professional sector, CNC milling machines are used for a variety of applications due to their effectiveness and efficiency. In the CNC milling machine industry They are an indispensable part of production, while at the same time they are important due to their availability and applicability workshops for home use for enthusiasts Model and are becoming increasingly popular in DIY projects.

- Industrial manufacturers rely on this CNC milling machineto meet the high standards in quality assurance.

- In workshops for Home use allows the CNC Technology allows hobbyists to implement their own ideas with precision and professionalism.

The wide range of possible uses shows how deep the CNC milling machine has become ingrained in the manufacturing culture and is now considered a cornerstone for innovation and development.

Important criteria when buying a CNC milling machine

Automated Precision: CNC milling machines use pre-programmed codes to create accurate cuts, engravings and shapes without manual intervention.

When purchasing one CNC milling machine Several factors play a crucial role in the successful implementation of your own projects. From my experience, I would like to highlight the key aspects that define the effectiveness and range of application of a CNC milling machine.

Working area and size of the machine

The Workspace A CNC milling machine must be adapted to the size of the workpieces to be machined. When creating large-format parts in the CNC milling machine woodworking For example, an appropriately sized machine is required. The space required for the machine itself is equally relevant - especially in the DIY sector, where there is often only limited space available.

Material compatibility and spindle performance

The variety of materials that a CNC milling machine can process ranges from CNC milling machine aluminum to various plastics and softer metals. At the CNC milling machine metal processing The performance of the spindle plays an important role. Allow higher spindle speeds more precise cuts and more efficient work processes. This is particularly crucial in model making, where a CNC milling model making must realize precise details.

Software and ease of use

For optimal handling it is Software for CNC milling machine decisive. It should not only be user-friendly, but also compatible with common file formats. Especially in the area CNC milling machine DIY Intuitively understandable software is worth its weight in gold, as it makes it much easier to familiarize yourself with the technology and is therefore also accessible for beginners.

- Checking the maximum work area for the project size

- Selection of material (aluminum, wood, metal) according to project requirements

- Evaluation of spindle performance according to material resistance and level of detail

- Comparison of software interfaces and their user-friendliness

Market overview and current CNC milling machine models

As an experienced user and expert CNC Technology I took an in-depth look at the current market. There is an extensive selection available professional CNC milling machines, the specially developed for industrial purposes were, as well as Small CNC milling, which are ideal for home use. Who one Buy a CNC milling machine online would like to find a wide one Range of options suitable for various requirements and budgets.

Different providers and price ranges

Competition in the market has created a variety of providers offering different models. This range extends from inexpensive entry-level models, which are available for just a few hundred euros, to high-quality machines with advanced technology and larger capacity are equipped and therefore also appeal to a correspondingly higher price segment. When purchasing online, it is therefore advisable to carry out careful research in order to be able to do so Best CNC milling machine for your personal projects and requirements.

Professional milling compared to entry-level models

Technology enthusiasts who are just starting out with CNC machining might consider one CNC milling for beginners-Decide model. These make it easier to get started with user-friendly interfaces and are often linked to helpful tutorials and communities. Offer in return professional CNC milling machines advanced features needed in industrial manufacturing, such as larger workspaces and more precise controls. Although the initial investment is higher, these machines are designed for durability and performance.

- Entry-level models with a limited range of functions and an attractive price-performance ratio

- Professional designs for demanding applications and long-term use

- Consider individual criteria such as size and material compatibility

Ultimately the decision is for one CNC milling machine for home use or a professional execution depends heavily on personal needs and the planned area of application. I recommend examining your own requirements in detail before purchasing and then choosing the model that best meets them.

Experience reports and user feedback

My intention as a specialist journalist is to provide you with authentic CNC milling experiences to bring closer. Through intensive study of User feedback CNC milling machine in online forums and analysis of numerous CNC milling machine test reports I have collected extensive information that will serve as a decision-making aid for potential buyers.

It is obvious that the real use of a CNC milling machine as well as the differentiated feedback from the users are elementary for a well-founded CNC milling machine review are. To give you an overview, I will present exemplary quotes and summaries from various sources.

After just a short training period, I was able to use the machine to carry out precise milling work on aluminum and hardwood. – a user from a specialist forum for CNC technology

- The range of functions and areas of application are rated as very positive

- What is noteworthy is the high level of precision when processing different materials

- The ease of use and support offerings from several brands receive consistently positive feedback

- Critical voices point out the importance of high quality accessories

With regard to personal CNC milling experiences I would like to emphasize that extensive research and obtaining user feedback are essential before investing in such a machine. The authenticity and diversity of user reports help to provide a realistic picture of performance and any weaknesses.

Discover Amazon – your source for powerful CNC milling machines that bring your projects to life.

- 【Double security design】 The protective design of a 5 mm translucent brown ...

- 【The two most important advantages of the offline controller】 1, you don't have to use the computer ...

- 【Support multi-spec laser modules】 This product is suitable for the spindle motor ...

Professional CNC milling machine: technical characteristics and performance

The performance of a professional CNC milling machine is defined by its technical characteristics. I set myself the task of taking a closer look at the aspects of precision, speed, construction and quality in order to determine what makes a CNC milling machine truly professional.

Precision and speed in the test

In my tests I found that the CNC milling precision decisively determines the quality of the end product. It is impressive to see how high-precision machines work even at high temperatures CNC milling speed deliver flawless results required in complex manufacturing processes.

Construction and workmanship quality

The CNC milling machine construction is an important indicator of the resilience and longevity of a machine. A solid construction, combined with first-class materials, ensures that even under difficult conditions CNC milling quality is maintained. These factors together help ensure that you can rely on a CNC milling machine in the long term.

Detailed expert test report of the TwoTrees TTC450 CNC milling machine

My expectations of them TwoTrees TTC450 were high because the search for a reliable one CNC milling facility is always a challenge. I was even more excited to see how the commissioning and the first test runs would work out.

setup and commissioning

The assembly of the TwoTrees TTC450 started off a bit bumpy at first. I noticed small difficulties attaching the limit switches. Nevertheless, after I had intensively studied the instructions, the setup was largely uncomplicated. At the CNC milling test-Phase I was particularly impressed by the user-friendliness of the software, which enabled seamless integration into my workflow. The milling machine was ready for use quickly and its operational readiness was beyond question after a short time.

Versatility and areas of application

The flexibility of the TwoTrees TTC450 in various areas of application was extremely impressive. Even though my primary focus is on working with wood and... plastics, the milling machine showed its capabilities across all materials. The CNC milling application area ranges from simple engraving to sophisticated 3D cutting projects. The generously sized cutting area enabled larger workpieces to be processed, which is of utmost importance for my projects.

Safety features of the TwoTrees TTC450

Another crucial point in my test was security. The TwoTrees TTC450 has several CNC milling machine safety-Elements that I really appreciated during my applications. The limit switches and the emergency stop button in particular provide a high level of safety and contribute to an undisturbed workflow. Especially during intensive use, it is reassuring to know that quick intervention is possible if something does not go according to plan.

In summary, the TwoTrees TTC450 is a serious consideration for anyone looking for a powerful, versatile and safe CNC router.

Software for CNC milling: selection and user tips

The fitting CNC milling software Finding it is a crucial step towards this Maximum get out of your machine. Software not only influences the precision and efficiency of manufacturing, but also the user experience. That's why I took the time to review some of the leading ones CAD/CAM software CNC Solutions to evaluate and valuable CNC software tips from my own experience and from experienced users.

Integration with common CAD/CAM programs

Integrating your CNC milling machine with proven CAD/CAM programs such as AutoCAD, SolidWorks or Fusion 360 can significantly increase your productivity. A seamless connection between design and manufacturing process minimizes errors and shortens the time from conception to the finished part.

User experiences with CNC software and interfaces

User experiences software CNC are fundamental to how quickly and effectively you can work with the CNC software. Many users of GRBL and other platforms emphasize how essential it is to take the time to understand the interfaces. Here are some tips that I have put together for you based on my research and personal experiences:

- Start with basic projects to get a feel for the software.

- Use online tutorials and forums to familiarize yourself with advanced features.

- Invest time in learning shortcuts and automation features

- Compare CNC software regarding support and update policies.

- Make sure your software is updated regularly to take advantage of the latest features and security improvements.

Even as an experienced user, I always find it helpful to be active in the community and exchange ideas with other users. This way you stay up to date with the latest developments User experiences software CNC always well informed.

The Shaper Origin – CNC technology meets augmented reality

My personal journey of discovery into the world of modern woodworking led me to... Shaper Origin led, a revolutionary combination of CNC milling and augmented reality. This innovative device opens the door to new dimensions of precision work, adding digital accuracy to woodworking that has never been achieved before.

New approach to handheld CNC in woodworking

Versatile use: CNC milling machines are used in various areas, such as model making, prototyping, furniture manufacturing or metal processing.

The Hand-held CNC milling machine With its unique design, it opens up new possibilities for carpenters and wood enthusiasts. In contrast to conventional stationary milling machines Shaper Origin I have the freedom to use CNC technology directly on the workpiece without any spatial restrictions.

The advantages of augmented reality technology in practice

The use of augmented reality in the Shaper Origin I am particularly excited because it creates a connection between visual control and machine precision. The integrated camera continuously tracks optical data Marker, which are placed on the work surface, ensuring extremely precise guidance of the milling machine. The use of augmented reality leads to a seamless and intuitive work process that CNC milling machine woodworking Takes innovation to a new level.

- Expanding the design options for projects

- Reducing the error rate through precise AR support

- Easier implementation of complex patterns

For me, the Shaper Origin not only represents the future of handheld CNC technology, but also a groundbreaking step in woodworking. It combines the best of traditional craftsmanship and digital precision.

Comparison of the best CNC milling machines for 2024: Which one is right for you?

The search for the best CNC router for home use is becoming increasingly more exciting because the offering is becoming more and more diverse. Let's take a look at two of the currently viewed models Take a look at what's available on the market and find out how they compare in direct comparison CNC milling in comparison hit.

Strengths and weaknesses of the top models in comparison

Both the 3018-PROVer from SainSmart and the PRT E-1500W 6040 model from fetcoi have properties that qualify them for various areas of application. While the 3018-PROVer impresses above all with its easy assembly and excellent customer service, the PRT E-1500W 6040 offers excellent performance thanks to its 4 axes and wide working range. A comprehensive analysis in CNC milling test 2024 will also take into account the durability and technical support of the manufacturers.

Criteria for the best CNC milling machine for the home

It's not just the technical specifications that decide whether a CNC milling machine is suitable Best CNC router for home use can be viewed. More CNC milling criteria, such as compatibility with different materials, the ease of use of the software and the size of the machine, also contribute to finding the machine that best suits your needs. Because every project brings its own challenges and requires a specially adapted machine.

- Ease of setup and use

- Compatibility with materials

- Workspace size

- Customer support and warranty

- Performance under continuous use

Consider all of these factors to decide which CNC router is right for your home needs.

The technical progress also does not stop at the tools. If the milling of small and large parts in former times still a comparatively laborious work, with which one hundred percent cleanliness could not be guaranteed, is, then offers the technology market today innovative devices, which put the same problem to an end. Professional CNC milling For this reason, they are as indispensable for craftsmen and model makers as the following tools that you can use Test-Vergleiche.com equally informative advice.

What are CNC milling?

CNC milling machines are often sold under the names portal milling machines or engraving machines. They are computer-controlled devices that enable precise processing of workpieces. In this way you can also do it at home Workshop Achieve accurate, industrial-quality results. Mainly come Professional CNC machines however, commercially used. In addition to the precision can be achieved with their help and unproblematic high repetition rates of the respective work steps.

And what exactly does CNC mean?

The abbreviation CNC stands for "Computerized Numerical Control". Translated, this means "computer-aided numerical control". In simple terms, CNC describes an electronic process in which machines (including CNC milling) are controlled with the aid of a computer.

The history of CNC milling

Simple milling machines settled on the market very early on. The first model invented the American Eli Whitney in the year 1818. Although it had nothing with today's technologically highly versed Industrial CNC milling machine common, but was a cornerstone for the general working procedure. Over the years the devices have been further developed until John Parsons - also an American - constructed the first paper tape-controlled NC machine for the US Air Force between 1949 and 1952. This was the direct predecessor of the microprocessor-based CNC milling machine that came onto the scene in 1976.

What is the main task of CNC milling?

CNC milling is used for the precise machining of various materials. This is done according to the so-called principle of chip removal. The main tasks include both detailed work and simpler processes such as drilling and rubbing. In addition, the devices are suitable for planing, Saw, filing, chiseling, engraving and turning. They are used, for example, in the form of Wood CNC milling, Aluminum CNC milling or metal CNC machines.

How does the CNC machine work?

The functional principle of CNC milling is extremely innovative and has little to nothing in common with that of the earlier milling machines. Rather, it is based on a technically sophisticated controller. In technical jargon they are referred to as a sensor-monitored, automated, numerically controlled control. The manufacturing process per se is based on the so-called CAM (computer-aided manufacturing) system. It has the task to transfer the data via CAD (for more information see our section "What is meant by a CAD program?")

can be programmed on the PC, converted into CNC data, which in turn are then transferred to the CNC router.

What is meant by a CAD program?

CAD is the abbreviation for “computer-aided design” – translated, this means something like “computer-aided design”. Explained in a generally understandable way, this process describes the creation of workpiece designs with the help of a computer application. CAD programs therefore replace traditional manual drawing of designs.

What are the two main types of CNC milling machine?

Basically, domestic and Industrial engraving machines into two main categories: the triaxial and the five-axis tiller. In which both species differ, we would now like to take a closer look:

3-axis milling machine:

First and foremost, the 3 axle mill distinguishes itself with regard to the field of application of its five-axis counterpart. Due to the significantly smaller size compared to this, it is mainly suitable for use in the home workshop or in small businesses.

5-axis milling machine:

With a five-axis milling machine, it is possible to machine workpieces in a very precise manner and in one step, where 3-axis milling machines reach their limits. An example of this are complex 3D constructions. In contrast to the smaller models, however, they are also much more expensive. For this reason, 5 axis milling is usually used in large companies.

Which materials can be processed with a CNC milling machine?

Good CNC machines can chop up a wealth of different materials. The most common ones include, for example:

- Wood

- Aluminium

- Plastic

- Precious metals

- Steel

- Bronze

- brass

Depending on the milling result, it is always important to select the right milling head. Please note in this context our section "Available accessories for CNC milling"!

Can you build yourself a CNC milling machine?

With a special one CNC machines kit Anyone who is a bit tech-savvy and does not shy away from the time required will be able to build a CNC milling machine independently. relevant Engraving machines forums and other specialist contact points on the Internet or in the trade provide corresponding information CNC milling construction instructions.

Probably the most significant advantage of a self-made apparatus refers to the acquisition costs, because these go in the case of a fully pre-assembled CNC milling bestsellers good and happy once in the high five-digit direction.

Most CNC machines kit Suppliers provide their customers with all the necessary parts. As an example: To the components of Stepcraft CNC router in the form of a kit (Portal Tiller Stepcraft 300) include:

Available accessories for CNC milling

CNC milling purchase recommendations often score points because there is a wide range of accessories available for them. This makes perfect sense, because it would be very annoying if you couldn't machine a certain workpiece because a suitable milling head was not available. This would also be the first possible accessory.

In addition, that includes CNC milling offer When it comes to accessories, there are also components for designing the work surface, such as vacuum tables or adhesive mats, as well as clamping devices, such as Vices or so-called clamping claws and measuring equipment. It also makes sense if spindles, guides and couplings can be purchased later. Radio remote controls are also available for controlling the machine.

How do you differentiate the operations of milling and turning?

As is well known, milling is a process in which a workpiece is cut through the Rotation of the milling head is machined. But what is the difference to turning? This question is relatively easy to answer:

Shaping

It moves when milling Tools in the material to be processed. The workpiece itself is fixed and therefore immovable.

lathe

When turning, the tool is fixed and the workpiece rotates.

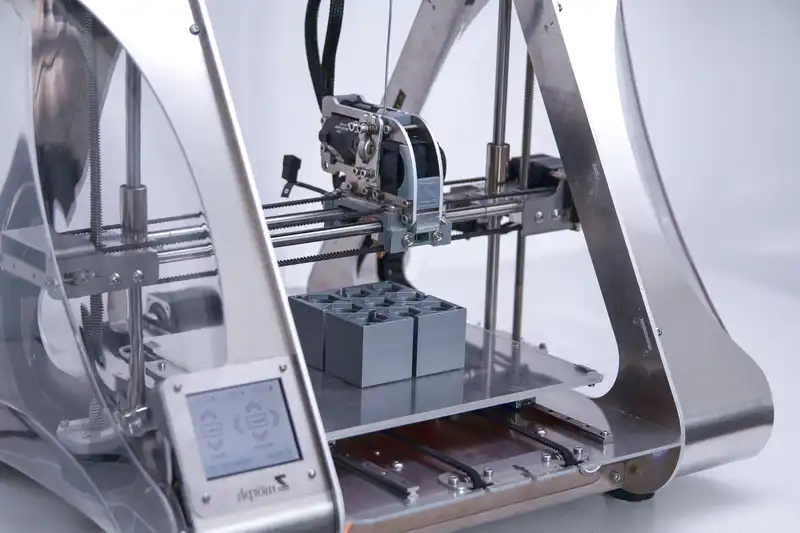

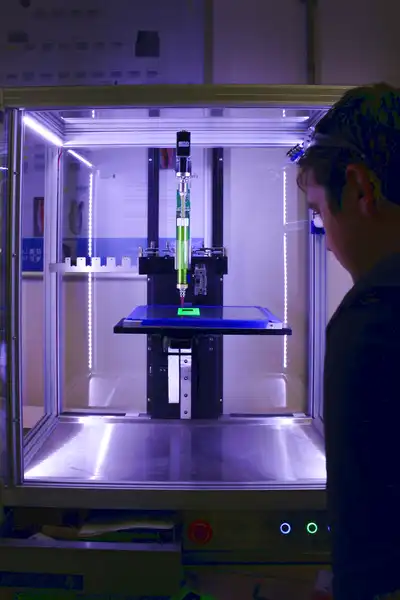

CNC milling machine vs. 3D Printers - Differences and Similarities

3D printer are on everyone's lips and are among the fastest developing technologies of our time. In this section, we would like to briefly and concisely explain to what extent the operation of a 3D printer is similar to that of a CNC milling machine and what the differences between the two are, from the perspective of differences and similarities.

similarities

Both the CNC router and the 3D printer offer the ability to handle many different materials, with the latter specializing in the design of plastic workpieces. Equally similar are the control commands that the user issues via computer software before production.

Differences:

The most significant difference between domestic or Industrial CNC machines and 3D printers are the executive tools. The former have different types of milling heads, the 3D printer, on the other hand, has one Print head that acts additively - i.e. with the help of materials. In other words: The 3D printer builds a workpiece from certain materials. The CNC milling machine, on the other hand, constructs assemblies by removing material. The counterpart to the additive approach is called reductive.

The most important criteria when purchasing a CNC milling machine

Which CNC milling machine ultimately the title Best Engraving not only depends on the individual requirements, but also on some other important aspects. Ideally, these should always be included in the purchase decision.

Kit or complete device:

The decision for one CNC milling kit or a complete device stands and falls with its own possibilities - especially with regard to the cost issue. Please also read our section "Can you build yourself a CNC milling machine?"!

Size:

What's in it? best CNC milling machineif she does not fit in the workshop? Large manufacturing companies are largely freed from this problem, but the hobby craftsman or modeler is definitely dependent on the appropriate size of the machine. So make sure you select a device with compatible dimensions.

Service:

The CNC machines offer ranges from beginners' devices to highly technical versions for professional, industrial use. Users in large companies are usually trained to work on CNC milling. Those who use the equipment privately, rely on a simple operation or clearly designed manuals. Make sure that this is also the case with the device you have selected.

Accesories:

Just about every material requires a specific milling head. This should always be available. In addition, it is advantageous if more accessory tools are available. Which of these can be, for example, clarifies our column "Available accessories for CNC milling".

User experience:

CNC milling experience reports can often give the final impetus to a purchase decision. However, they are only of value if they come from trusted sources. Good points of contact for meaningful CNC machines reviews are for example CNC milling forums.

Quality and workmanship:

An good engraving machine should be able to fulfill any task that is given to it without restrictions and with a satisfactory end result. However, it can only do this if it is qualitative high quality and first class workmanship at a hunt. Cheap CNC machines are not always bad, but all contingencies in this regard should be excluded before making a purchase.

Advantages and disadvantages of CNC machine

Benefits

Precise and easy machining of complicated workpieces made of different materials possible

preprogrammed work steps run independently without constant monitoring

CAD software can be installed on standard PC and used from there

wide range of accessories available

less time spent

several steps possible at the same time

Disadvantages

comparatively high acquisition costs

CAD program can be complicated for beginners

Maintenance and repair of machine problems more difficult

Who manufactures CNC milling?

There are countless manufacturers who CNC machines purchase recommendations speak out for their products. Reliable devices that have proven themselves in practice, for example, keep these brands ready:

In addition, count Stepcraft CNC machines to the bestsellers.

Where can I buy CNC milling?

You can Order engraving machines online or purchase them from a specialist tool shop. For the first option mentioned, online wholesalers are available, for example Amazon or the CNC milling shops the manufacturer. Big DIY stores also keep bargains on offer from time to time CNC milling outlets ready. No matter which point of contact you choose: a more detailed CNC machines price comparison is worthwhile in principle.

Has Stiftung Warentest already dealt with the subject of CNC machines?

An explicit one CNC milling Stiftung Warentest Test there is not so far and for this reason, no CNC milling test winner, which has been chosen according to the evaluation guidelines of the Independent Consumer Portal. On the subject of tools in general, however, have already done some tests that are worth watching. However, if you are looking for special CNC milling knowledge, this one has it CNC machines purchase advice certainly helped.

Accessories and expansion options for CNC milling

As an enthusiastic user of CNC Technology I know that's the right thing CNC milling accessories and meaningful CNC milling extensions are crucial in order to fully exploit the possibilities of my machine. Over time, I have learned that there are a wide range of CNC milling accessories that can help make projects more efficient and precise.

- Improved spindles: They are the heart of precise cuts and high working speeds.

- Additional axes: A 4th or even 5th axis opens up new processing options and significant increases in the precision and complexity of the workpieces.

- Special tool holders: These enable quick tool changes and increased versatility of CNC work.

Smaller but equally important ones should not be neglected Accessories for CNC millingthat belong to daily use:

- Collets: Helpful for secure and precise clamping of the milling tool.

- Various milling cutters: Quality and type are crucial for the processing result.

- Cooling systems: They are essential to ensure the longevity of the cutters and the materials to be processed.

The investment in CNC milling upgrades can be significant, but the increased efficiency and expanded manufacturing capabilities justify the expense in most cases. Paying attention to the quality and compatibility of accessories is crucial to getting the most out of my CNC router.

Amazon - The best choice for professional milling with our advanced CNC milling machines.

Price comparison and cost-benefit analysis

As an enthusiastic user and long-time expert in CNC technology, it is important to me to share my experiences with regard to the economic aspects of investing in a CNC milling machine. The market offers an almost unmanageable range of options that are attractive to both CNC novices and experienced professionals. To discover an optimal price-performance ratio among these, a thorough one is necessary CNC milling machine price comparison essential - an aspect that goes far beyond the initial purchase and also extends to operating costs.

Investment considerations for beginners and professionals

When looking at the cost-benefit calculation of a CNC milling machine, I always weigh the price of a machine against its efficiency, flexibility and ultimately the expected service life. The CNC milling investment is a long term; That's why I analyze not only the acquisition costs, but also the expenses for maintenance and possible expansions. This results in meaningful conclusions about the expected return on investment, which significantly influences the decision-making process.

Guide to budget planning and financing options

Before I decide on a machine, I personally recommend creating a realistic budget that takes all relevant cost factors into account. This includes not only the purchase price, but also, for example, training on software use and investments in safety equipment. The CNC milling financing can take different forms – from one-off purchases to rental or leasing models. It is important that the chosen option fits seamlessly into your own financial concept and still leaves enough scope for future developments. This is how you secure your future viability and ensure your own CNC milling machine budget to use optimally.

FAQ

What is special about a CNC milling machine?

A CNC milling machine is a computer-controlled machine that processes materials such as wood, metal or plastic can cut, engrave and shape with high precision. CNC technology can create intricate designs and shapes that would be difficult or impossible to achieve using manual methods.

Who is suitable for buying a CNC milling machine?

CNC milling machines are suitable for industrial applications as well as for hobbyists and makers. They play a crucial role in the manufacturing industry, but are also very popular for use in private workshops and model making.

How do you determine the right size and working area of a CNC milling machine?

The choice of size and workspace depends on the projects you want to implement. For larger workpieces, a milling machine with a wider working range is necessary, while smaller projects can also be realized with more compact machines.

Which materials can be processed with a CNC milling machine?

CNC routers are versatile and can process a variety of materials, including aluminum, wood, various metals, plastics and composite materials. The material compatibility is determined by the used CNC tools and the spindle performance of the machine is determined.

How important is the software for operating a CNC milling machine?

The software plays a central role in how a CNC milling machine works. It not only enables the design and planning of projects, but also controls the milling machine. User-friendly software makes it easier to get started and use the machine optimally.

What should you consider when choosing a CNC router for home use?

When choosing a CNC router for your home, you should pay attention to the machine size, system compatibility, supported materials and, most importantly, safety features. A good price-performance ratio and customer service are also important criteria.

How important is user feedback when deciding on a CNC milling machine?

Experience reports and ratings from other users are valuable for getting an impression of the reliability, performance and user-friendliness of various CNC milling machines. They help identify machine strengths and weaknesses and inform your choice.

What characterizes a CNC milling machine with high precision?

A high level of precision is guaranteed by features such as precise spindle guidance, stable mechanical engineering and advanced control technology. Machines that work precisely even under constant load are particularly reliable and produce high-quality results.

Are the safety features important on a CNC milling machine?

Yes, safety features such as limit switches, emergency stop switches and protective covers are very important. They protect both the machine and the operator from damage and contribute to the long-term functionality of the CNC milling machine.

Can you assemble a CNC milling machine yourself?

Yes, there are CNC milling machines in kit form specially designed for DIY lovers became. Such kits require a certain technical knowledge and patience, but also offer the opportunity to customize the milling machine and understand the structure in detail.

How is the Shaper Origin different from other CNC milling machines?

The Shaper Origin combines CNC technology with augmented reality, enabling hand-held CNC machining. This innovation allows users to work intuitively and flexibly while benefiting from the precision of digital manufacturing.

How much do you have to invest for a good CNC milling machine?

The costs for a good CNC milling machine vary greatly and depend on various factors such as size, functionality and brand. Inexpensive entry-level models are available starting at just a few hundred euros, while professional industrial machines are in higher price ranges.

Are there subsidies or financing options for purchasing a CNC milling machine?

Yes, there are various financing options such as rental purchase, leasing or loans that can be considered when purchasing a CNC milling machine. Funding varies regionally and should be researched individually.

Which accessories are recommended for CNC milling?

Useful accessories for CNC milling include various types of milling cutters, collets, cooling systems and dust extraction. Extensions such as additional axes can increase the functionality of the machine even further.